The main goal of this project is to select coating materials and technologies to increase the power conversion efficiency of multi-junction (III – V) solar cells (MJSC) for space applications. The final purpose is to demonstrate a performance increase at bare solar cell level of at least 0.5%, with respect to the competing current state of the art solutions. This goal is pursued by engineering for a broadband antireflection coating (ARC), in the wavelength range from 250 to 1800 nm, better surface and edge passivation and more efficient electrical contacts.

Innovative materials are explored: wide band gap materials as components of a multilayer broad-band ARC and passivation layers for the front of the MJSC

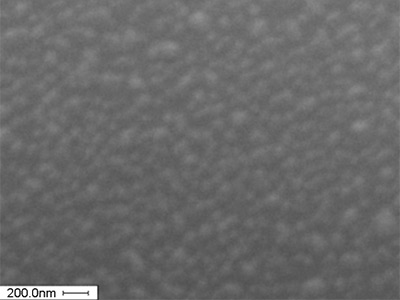

Sputtering is the reference thin film deposition technique, nevertheless less conventional techniques (PLD and PED) are tested for their unique ability to deposit highly adherent, dense and low roughness coatings of a variety of materials at low substrate temperature.

In particular PED technique is employed at IMEM to growth thin film structure on top of the MJSC after the optical simulations of the ARC design and SC structure.

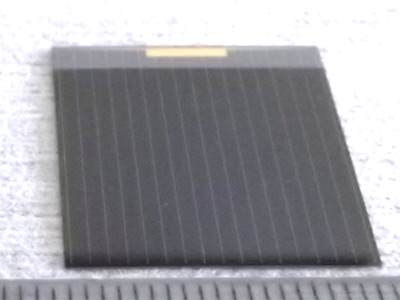

The coatings developed in Nanocoat project integrate passivation layer for minimizing the surface recombination velocity at the front and back surfaces of the MJSC. New approaches for the reduction of the reflection losses are theoretically and experimentally studied using as baseline CESI space triple junction solar cells CTJ30 already qualified as standard and thin version.

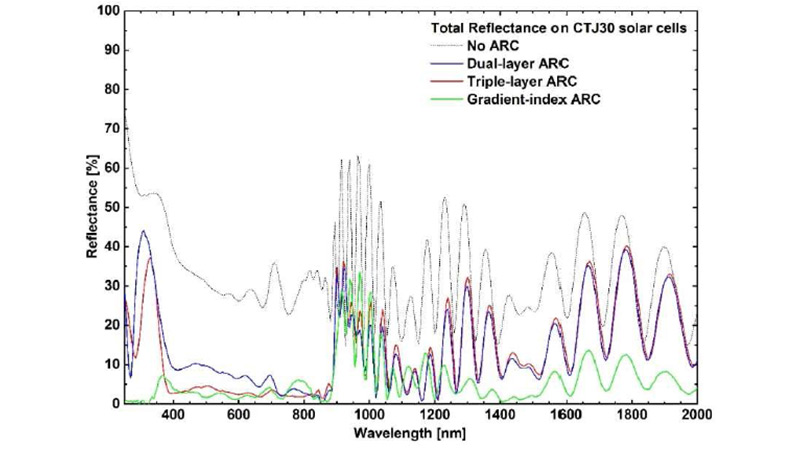

Two new antireflection coating (ARC) designs demonstrate to be superior with respect to standard CESI antireflection coating design: a triple-layer structure and a gradient-index structure. Both structures are fabricated on top of 2x2 cm2 solar cells, in order to assess their optical and electrical performance before the scale-up towards 4x8 cm2 solar cells. In the new ARC designs the surface and edge passivation are provided by the conformal deposition of the wide band-gap metal oxides. The PLD and PED techniques ensure that both the surface and the edge of the solar cell substrates are covered with high-quality films during the deposition process.

The triple-layer ARC design is determined using optical simulation software suitable to simulate both the electrical and the optical behaviour of a multi-junction solar cell. The investigations allowed to define Nb2O5 / Ta2O5 / SiO2 as the most promising architecture to improve the standard ARC.

The triple-layer ARC structure has its best optical response in the 400-900 nm spectral range whereas the gradient-index ARC provides an overall reduction of the total reflectance.

The CTJ30 CESI solar cells show a significant increase in the electrical performance of the device coated with the two new ARC structures with respect to the standard. The efficiency increase is achieved. Several devices are successfully tested showing no degradation of the electrical parameters after irradiation, thermal shock and humidity & temperature tests.

Project Partners

- RINA CONSULTING

- CESI

- IIT

- CNR-IMEM

Publications

"Effective Coating for High Efficiency Triple Junction Solar Cells", 2019 European Space Power Conference (ESPC) (DOI: 10.1109/ESPC.2019.8932034)