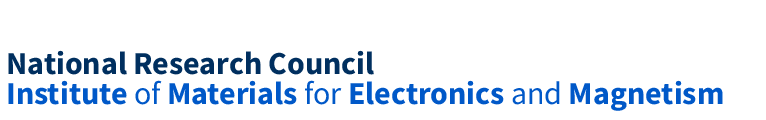

Micro Electro Mechanical System and Microsystem define both a class of devices and associate technologies, which have been standardized and developed in the last two decades. They represent a key for miniaturization, integration and high-volume production for a new generation of sensors. Fundamental competences for design and fabrication of MEMS and microsensors are well consolidated in the institute and we developed several prototypes for different industry application and fundamental and applied research, among which we mention:

- gravimetric microsensors (microcantilevers), also in the form of an array, for chemical and pressure (vacuum) measuring;

- hazardous and combustible gas microsensors based on micro hot-plate technology and integration of a proper nanostructured active material;

- sensors and sensor based on electrical transduction (Multi Electrode Arrays, Organic Electrochemical Transistors (OECTs), EGOFETs, …) with scale down capability to nanostructures;

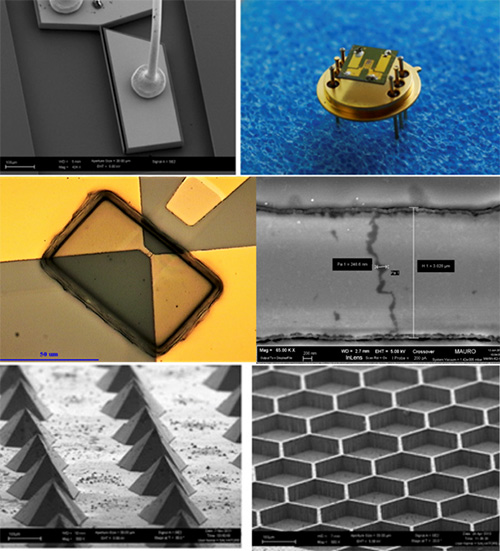

- force sensors based on silicon resonators and high-stress SiN membrane resonators, with force sensitivity enabling the observation of quantum effects induced by optomechanical interaction, both in the behaviour of the oscillators and in the properties of radiation itself.

Different research groups of the IMEM institute have also consolidated expertise in the main technological aspects related to the micromachining of MEMS-based devices and their integration in experiments of fundamental physics.

In fact, related to the device, the technologies are based on different process steps that relate to:

- growth of thin films both conductive and dielectric (thermal and e-gun evaporation of metals, Plasma Enhanced Chemical Vapor Deposition (PECVD), magnetron sputtering;

- lithographic technologies for devices patterning (optical lithography with front & backside alignment, LIGA-like processes using SU-8);

- technologies for wet etching, dry etching (plasma etcher and Reactive Ion Etcher);

- optical interferometry, electromechanical and electronics technologies for low noise sensing, thermal stabilization, tuning of the mechanical susceptibility through feedback techniques, data analysis and processing.