Devices and detectors for X and gamma rays

The applications of X- and gamma-rays detectors span several fields from specific research topics (e.g., astrophysics, fundamental physics) to more practical sectors related to the everydays life (inspection of industrial products, security controls).

In the former case, the capability of detecting this type of light has a crucial role in the observation of celestial bodies and cosmic radiation. In fact, the light coming from space covers the whole electromagnetic spectrum and, thus, its measurement in the keV to MeV energy band is essential to complete the picture. In the latter case, the penetrating power of high energy photons led to the realization of new inspection techniques able to literally “see” inside an object without breaking or opening it. This process is called “non-destructive testing” (NDT) and represented a breakthrough in industry since it allowed to rapidly verify the quality and to detect the presence of contaminants in the final industrial product.

IMEM is active since several years in both these sectors thanks to its CZT-based detectors.

Deep UV detectors

The stratosphere ozone layer acts as a filter for the far UV-light emitted by the sun. For this reason, there are no natural sources for radiation in the 230-270 nm range (UV-C).

Artificial sources of UV-C light are e.g. combustion flames, corona discharge, mercury lamps.

In collaboration with the Department of physics of Parma University, we are developing UV-C solar blind sensors based on gallium oxide to be employed for example in monitoring the faults of electrical power lines, in fire detection or in UV-C sterilization appliance

Gas sensors

Gas sensors are widely use for different industrial applications, from workers safety from the possible presence of hazardous gases or volatile compounds, to leakage check, from the monitoring of processes that must or must not emit specific volatile chemicals, to the analysis on production lines or closed environments.

The availability of low-cost and low-power-consumption sensors, such as those that are based on nanostructured metal oxides, makes possible the creation of distributed networks with multiple sensors located in different positions of factories and plants, that can interact with alarm, safety or production systems. This is one of the bases of the so called "Industry 4.0", in which industrial automation integrates new productions technologies to improve working conditions, to create new business models and to increase productivity as well as quality in production plants.

This kind of sensors kan be used individually, but more often they are used in sensors arrays, especially when complex environments and measurement conditions are faced. Unfortunately, indeed, this kind of sensors is sometimes even to much sensible or it is able of to detect a very large number of gases, but without the capability of directly discriminate and quantify each constituent gas.

For this reason we developed in the last years an innovative approach that makes use of several sensors of this kind, all integrated in a single device. Their response are then combined and analysed with "machine learning" techniques, allowing the system to identify the present gases and their concentration in air.

MEMS

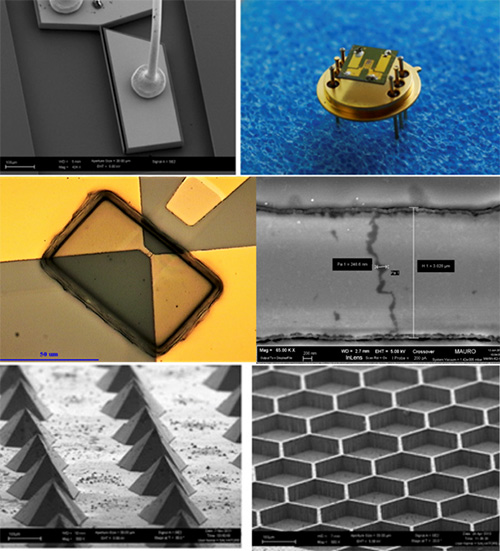

Micro Electro Mechanical System and Microsystem define both a class of devices and associate technologies, which have been standardized and developed in the last two decades. They represent a key for miniaturization, integration and high-volume production for a new generation of sensors. Fundamental competences for design and fabrication of MEMS and microsensors are well consolidated in the institute and we developed several prototypes for different industry application and fundamental and applied research, among which we mention:

- gravimetric microsensors (microcantilevers), also in the form of an array, for chemical and pressure (vacuum) measuring;

- hazardous and combustible gas microsensors based on micro hot-plate technology and integration of a proper nanostructured active material;

- sensors and sensor based on electrical transduction (Multi Electrode Arrays, Organic Electrochemical Transistors (OECTs), EGOFETs, …) with scale down capability to nanostructures;

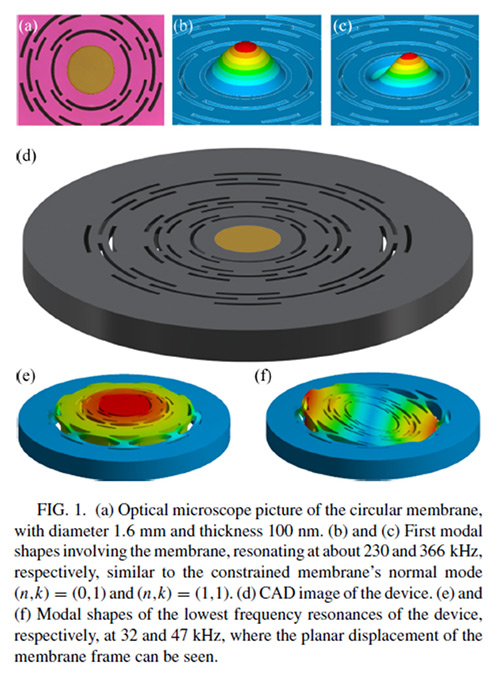

- force sensors based on silicon resonators and high-stress SiN membrane resonators, with force sensitivity enabling the observation of quantum effects induced by optomechanical interaction, both in the behaviour of the oscillators and in the properties of radiation itself.