Chemoresistive sensors for gases and volatile organic compounds (VOC) base their working principle on the variation of their electrical resistivity when they come into contact and react with specific substances in the surrounding environment. So, it is possile to measure the amount of gas or VOC near the sensor by simply measuring its proportional resistance.

This kind of sensors, mainly produced with metal oxide semiconductors, is characterized by a very high sensitivity and low cost. These properties make them the ideal solution for a lot of applications in different fields, from safety and security checks to air pollutant measurement, from medical technologies to industrial ones for the monitoring on production lines. Being generally small, cheap and having low power consumption, allows them to be easily integrated in distributed sensor networks or in daily use objects, in view of the expansion of IOT (Internet of Things") emerging reality.

IMEM develops materials and processes for the realization of chemoresistive gas sensors based on oxide nanostructures. IMEM can count of an almost twenty year long experience in the growth of nanostructured materials, in their characterization (morphology, structure, functionality), in device realization and their test, in modelling and data analysis..

Oxide nanostructures

If the metal oxides that are commonly used as chemoresistors are synthetised in form of nanostructures, it is then possible to exploit the nano-scale peculiarities to improve gase snensors. Indeed, nanostructures have an extremely high surface/volume ratio (one gram of these materials can have up to the same surface of a soccer field) and since the sensible part of oxides lies on their surface (they come in contact with the gases and the other compounds in air through it), it is easy to understand how this property can improve sensors capabilities. Moreover, some of these nanostructures are more stable in time and can create porosities of different size.

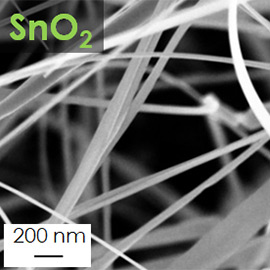

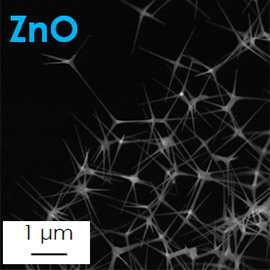

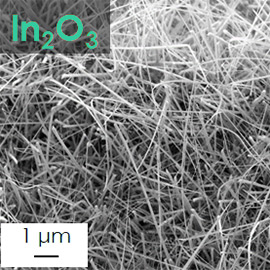

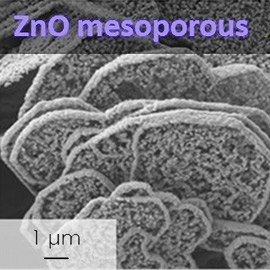

Our laboratories are equipped with reactors fo vapour phase synthesis and solvo-thermal growt apparatus for the synthesis of zinc-, tin-, indium-, gallium-, copper- and lead-oxide nanostructures. Most of them are suitable for the production of gas sensors. Above all, tin oxide and zinc oxide (which can be obtained in different morphologies, such as nanowires, nanorods, nanotetrapods and mesoporous nanostructures)

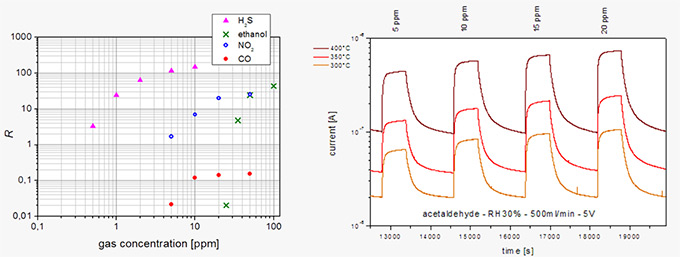

It is also possible to modify the sensor functionality through the coupling with different materials at the nano-scale, such as inorganic or organic semiconductors, or metals (At, Ag, Pt, Pd...). In this way it is generally possible to improve sensor's sensitivity and/or selectivity

Prorotypes

Procedures have been defined to produce gas sensor devices based on nanostructures or films.

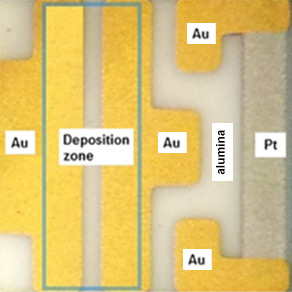

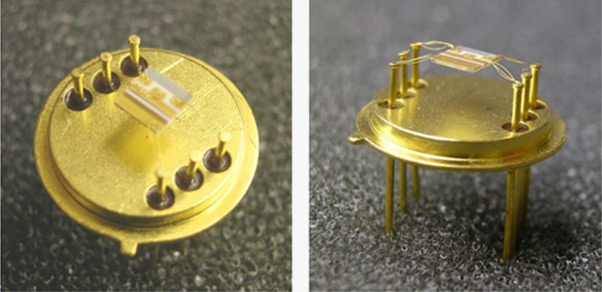

The sensing material (metal oxide) is directly grown or can be later deposited on alumina substartes, within a specific area where sensing contacts are present (on the left in the following figure). A Pt resistive stripe is deposited on the same substare and it can heat by joule effect the whole substrate up to 500°C. All of this is then bonded in a floating configuration (to avoid heat dissipation) on a TO8 holder.

This procedure allows us to create sensors indipendently on the nature and the morpholoy of the used sensing material (free standing nanostructures or film).

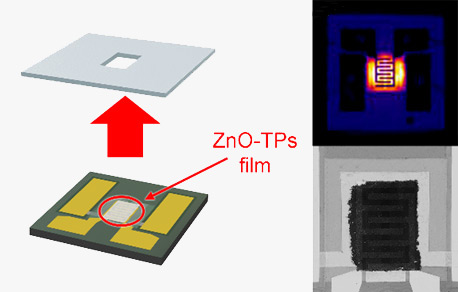

An evolution of this kind of device can be also made by means of MEMS technology. It is made on a silicon nitride micromembrane and, since both the sensing area and the volume to be heated is much smaller in this case, power consumption is strongly reduced.

Up to date, prototypes have been made to study the sensing properties of:

- SnO2 nanowwires

- ZnO nanotetrapods

- ZnO mesoporous platelets and nanobelts

- ZnO thin films deposited by sputtering

Sensor test

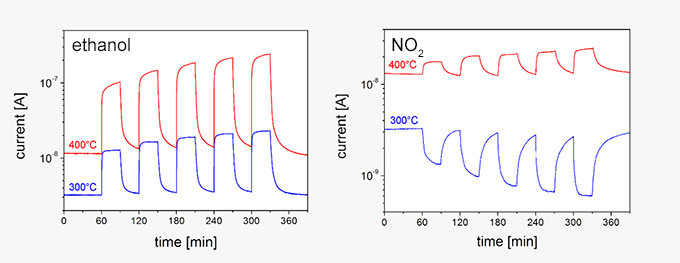

Our laboratories are also equipped with instrumentation dedicated to the functional characterization of proptotypes: a thermostatic chamber with humidity control, multiple test gas or volatile compound available and mixable (for example CO, NOx, alcohols, benzene, aldehydes, methane) even at very low concentrations (ppm, ppb), automatic control system for flows, temperature and data recording.

Data analysis and modelling

Resistive sensors based on nanostructured metal oxides, whose fabrication is relatively simple and cheap, and whose dimensions allow their integration down to dimensions similar to those of a smartphone, are nowadays widely employed.

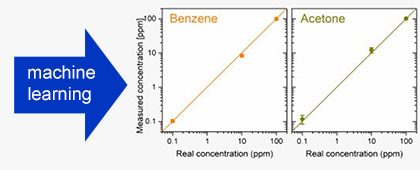

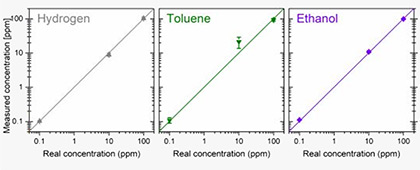

Unfortunately, this type of sensors is sometimes too sensitive and perceives almost every gas, without the capability of directly discriminating and quantify different gases. For this reason, the innovative approach that we have developed in recent years involves the use of some of these sensors integrated in a small chip (the size of a few tenths of a millimeter) subjected to a thermal gradient. The responses of the various sensors are combined and analyzed with machine learning techniques, making the system capable not only of identifying the gas present, but also its concentration.

The ability to estimate the concentration of each gas also puts the points on lines rather than in small spherical clouds.

The use of supervised learning techniques requires a sensor calibration step, but allows to estimate the concentration of the classified gas with a very good error (around 10-15%).