Heusler alloy thin films and nanostructures

Heuslers are a huge class of ternary intermetallic compounds, with chemical formula X2YZ (full Heusler) or XYZ (half Heusler), X and Y typically being transition metals and Z being a main group element. These compounds show an impressive variety of physical properties, such as, for instance, superconductivity, thermoelectricity, topological insulating properties, first-order or metamagnetic transitions, high magnetic anisotropy, high spin polarization. We grow epitaxial thin films of magnetic Heusler compounds by a sputtering apparatus. Epitaxial thin films both represent model systems for the fundamental investigation of bulk material properties, since the structural order has strong impact on the properties of Heusler compounds, and are itself highly attractive for the integration into a diversity of micro- and nano-devices. Our activity is mainly focused on two compounds, as shown in the highlights below: magnetic shape-memory Ni-Mn-Ga and high-anisotropy tetragonal Mn-Ga.

Highlights

-

Magnetic shape-memory Ni-Mn-Ga films

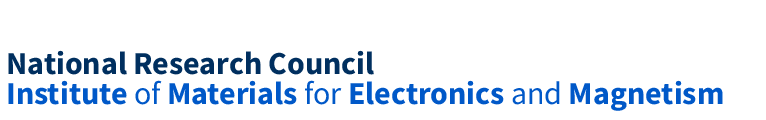

Stoichiometric Ni2MnGa is a full Heusler compound and a model system for magnetic shape-memory materials, in which huge elastic deformations can be driven by temperature and magnetic field. At the origin of the effect is a magnetostructural transition from a high symmetry L21 phase (austenite), stable at high temperature, to a lower symmetry phase (martensite), stable at lower temperature. The martensitic phase shows different crystal structures depending on compositional variations around the 2-1-1 stoichiometry. We grow the films epitaxially at high temperature in the austenitic phase, on MgO(100) or Cr/MgO(100). After transforming to the martensitic phase, they show a complex pattern of twin variants. We have engineered the film microstructure: we have obtained a variety of martensitic patterns by modifying the growth conditions, applying a stress during or after growth and annealing the films; we have also in-depth investigated the relation between the details of twin variants microstructure and the magnetic and magneto-thermal properties of the films (https://doi.org/10.1016/j.actamat.2020.01.049 and 10.1002/adma.201502072).

Evolution of the twin microstructure in a 200 nm Ni-Mn-Ga film after application of different external stimuli: temperature, mechanical stress and magnetic field; film microstructure is evident in the Scanning Electron Microscopy images; the resultant magnetic microstructure evidenced by Magnetic Force Microscopy reflects the orientation of the easy-magnetisation axes in different types of martensitic twin variants (X or Y type)

Evolution of the twin microstructure in a 200 nm Ni-Mn-Ga film after application of different external stimuli: temperature, mechanical stress and magnetic field; film microstructure is evident in the Scanning Electron Microscopy images; the resultant magnetic microstructure evidenced by Magnetic Force Microscopy reflects the orientation of the easy-magnetisation axes in different types of martensitic twin variants (X or Y type)

Reprinted from “Martensite-enabled magnetic flexibility: The effects of post-growth treatments in magnetic-shape-memory Heusler thin films” – M. Takhsha Ghahfarokhi et al.– Acta Materialia 187, 135 -145 (2020) – Copyright (2020), with permission from Elsevier https://doi.org/10.1016/j.actamat.2020.01.049

-

Magnetic shape-memory Ni-Mn-Ga nanodisks

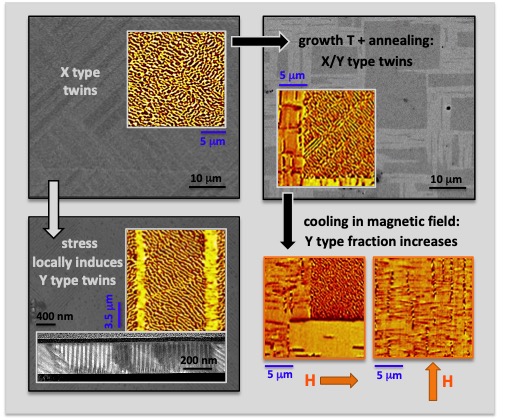

Starting from a 75 nm thick epitaxial Ni-Mn-Ga film, we have realised magnetic shape memory free-standing nanodisks with 650 nm size and demonstrated that temperature and magnetic field can be exploited to modify the microstructure and induce an areal strain in the nanodisks. The nanodisks have been produced by a self-assembly nanolithography approach on a large area (∼cm2), and subsequent selective wet-etching of the sacrificial underlayer. The martensitic twin microstructure is characterised by two different types of twin variants, X and Y type; their relative areal fraction and spatial distribution are affected by the lateral confinement and release from the substrate. These details and their correlation with the thermo-magnetic actuation have been investigated by different electron microscopy techniques, including electron holography. A reversible areal strain (up to 5.5 %,) can be achieved and tuned in intensity and sign (i.e. areal contraction or expansion) by the application of a magnetic field.

a) Bright field TEM image of a group of three martensitic Ni-Mn-Ga nanodisks; b) Lorentz microscopy image showing the magnetic configuration of the disks as-detached from the substrate; c) Lorentz microscopy image taken after the thermal cycle performed with H = 0, a rearrangement of the magnetic domains occurs to minimize the stray field.

Reference: https://doi.org/10.1002/smll.201803027

-

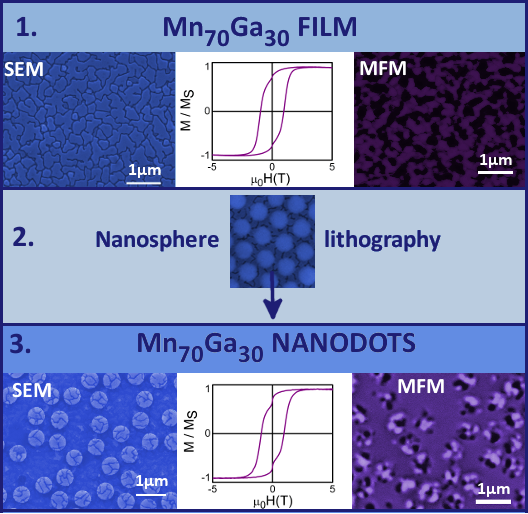

High-anisotropy tetragonal Mn-Ga

MnxGa1-x (0.66<x<0.75) is a full Heusler compound, which shows, in the metastable tetragonal D022 phase, unique properties for spintronic memories and devices. The material exhibits low saturation magnetization, low Gilbert damping, high uniaxial magnetic anisotropy, high magnetic Curie temperature and spin polarization. This phase is also interesting for the development of permanent magnets with maximum energy products halfway between Nd2Fe14B and Ba(Sr)Fe12O19. We have grown epitaxial MnxGa1-x thin films (x=0.70, 0.75) in the D022 phase at different thicknesses on SrTiO3 (STO) and (LaAlO3)0.3(Sr2TaAlO6)0.7 (LSAT) substrates. The growth on LSAT, due to the larger misfit compared to STO, generates a distortion of the tetragonal lattice, which promotes enhanced magnetization and magnetocrystalline anisotropy (https://doi.org/10.1063/1.5004594). We have also patterned 600 nm nanostructures in the film by a self-assembly nanolithography approach (http://dx.doi.org/10.1016/j.apsusc.2016.07.029).

Morphology and magnetic properties of a 40 nm Mn70Ga30 epitaxial film and patterned 600 nm nanodots, as obtained by Scanning Electron Microscopy (SEM), Magnetic Force Microscopy (MFM) and SQUID magnetometry with field applied perpendicular to the film plane; both the film and nanodots show perpendicular magnetic anisotropy and coercivity around 1T

Reference: Highlight on Advances in Engineering 2017

Main publications

- “Martensite-enabled magnetic flexibility: The effects of post-growth treatments in magnetic-shape-memory Heusler thin films” – M. Takhsha Ghahfarokhi, F. Casoli, S. Fabbrici, L. Nasi, F. Celegato, R. Cabassi, G. Trevisi, G. Bertoni, D. Calestani, P. Tiberto, F. Albertini – Acta Materialia 187 (2020) 135 – https://doi.org/10.1016/j.actamat.2020.01.049

- “Magnetic Shape Memory Turns to Nano: Microstructure Controlled Actuation of Free-Standing Nanodisks” – M. Campanini, L. Nasi, S. Fabbrici, F. Casoli, F. Celegato, G. Barrera, V. Chiesi, E. Bedogni, C. Magén, V. Grillo, G. Bertoni, L. Righi, P. Tiberto, F. Albertini – SMALL 14 (2018) 1803027 - https://doi.org/10.1002/smll.201803027

- “Achieving Giant Magnetically Induced Reorientation of Martensitic Variants in Magnetic Shape-Memory Ni-Mn-Ga Films by Microstructure Engineering” – P. Ranzieri, M. Campanini, S. Fabbrici, L. Nasi, F. Casoli, R. Cabassi, E. Buffagni, V. Grillo, C. Magen, F. Celegato, G. Barrera, P. Tiberto, F. Albertini – Advanced Materials 27 (2015) 4760 - DOI: 10.1002/adma.201502072

- “MnxGa1-x Nanodots with High Coercivity and Perpendicular Magnetic Anisotropy” – J. Karel, F. Casoli, P. Lupo, F. Celegato, R. Sahoo, B. Ernst, P. Tiberto, F. Albertini, C. Felser – Applied Surface Science 387 (2016) 1169 – http://dx.doi.org/10.1016/j.apsusc.2016.07.029 & Highlight on Advances in Engineering 2017

- “Enhanced magnetization and anisotropy in Mn-Ga thin films grown on LSAT” – J. Karel, F. Casoli, L. Nasi, P. Lupo, R. Sahoo, B. Ernst, A. Markou, A. Kalache, R. Cabassi, F. Albertini, C. Felser – Appl. Phys. Lett. 111 (2017) 182405 – https://doi.org/10.1063/1.5004594

Custom-made films, multilayers and nanostructures

We grow thin films, multilayers and nanostructures of magnetic 3d metals and alloys, designing the single phase material or nanocomposite to obtain the desired magnetic properties or study a specific physical problem. The growth is realised by a sputtering apparatus. We have been able in several cases to achieve the control of the magnetic and functional properties by in-depth studying, and finally controlling, structure and morphology. A couple of remarkable examples on hard and soft magnetic materials are presented as highlights. Another example are magnetic multilayers, such as, multilayers with noble metal spacers, which we have realised and studied for perpendicular magnetic anisotropy memories and magneto-plasmonic sensors, or heterostructures including other kinds of layers showing properties relevant for spintronics.

Highlights

-

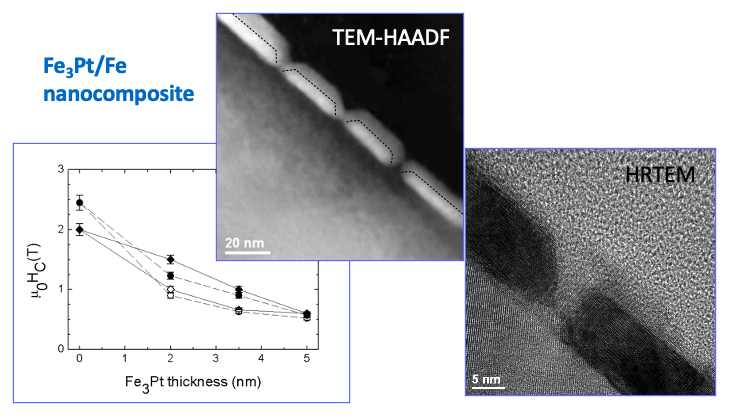

Exchange-coupled soft/hard nanocomposites

The nanoscale interaction between a soft and a hard magnetic material can be exploited to tune the magnetic properties of a soft/hard composite system, a concept that became popular in 1991 with the proposal to enhance the maximum energy product of permanent magnets by adding a nanostructured soft magnetic phase with high saturation magnetisation to a hard magnet with high magnetocrystalline anisotropy. Starting from 2005, soft/hard nanocomposite systems have been widely studied for magnetic recording media with the aim of improving writability, by reducing the hard phase coercivity thanks to the exchange-coupling with the soft phase. The concept has recently received renewed interest for spintronic devices based on spin-valves or magnetic tunnel junctions, where the soft layer can have tilted magnetisation angle thanks to the coupling to the hard layer. We have proposed and realized different exchange-coupled nanocomposites, i.e., epitaxial heterostructures where a magnetically soft phase is grown onto a magnetically hard phase with huge perpendicular magnetic anisotropy (L10-FePt): Fe/FePt; Fe3Pt/FePt; graded-anisotropy FePt by ion irradiation.

Structure and morphology of an epitaxial nanocomposite, as analysed by different transmission electron microscopy (TEM) techniques (middle and right panel); the soft Fe3Pt phase grows pseudomorphic on top of the hard L10-FePt phase; the perfect structural coherence allows to reach the strong coercivity reduction shown in the graph on the left

Reference: "Exchange-Coupled Composite Media", F. Casoli et al. – in Ultra-High-Density Magnetic Recording: Storage Materials and Media Designs, pp 279-326, Pan Stanford Publishing, 2016. Editors: G. Varvaro, F. Casoli.

-

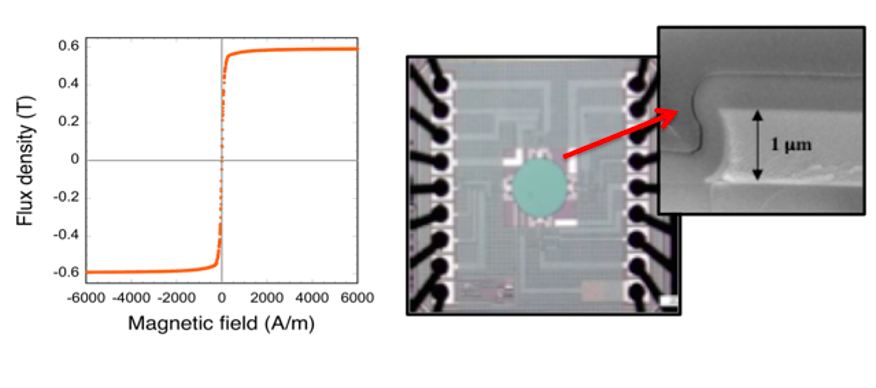

Soft magnetic thin films for magnetic sensors

In recent years, an increasing interest in contactless current sensors for energy metering and compass feature of mobile consumer applications has triggered the development of integrated magnetic sensors. In most of the commercial sensor integrated circuits (ICs), a thick magnetic concentrator is inserted in the IC by a post-process (mechanical bonding and etching, or electroplating). We have collaborated with a microelectronics company to directly integrate a magnetic concentrator thin film into a magnetic Hall sensor. A soft magnetic layer with optimised magnetic and mechanical properties has been integrated into a BCD technology using standard 8” CMOS equipments, thus reducing the sensor production cost and improving the control of the manufacturing process compared to competing technologies requiring post-processing steps.

Photograph of the Hall sensor with detail of the magnetic layer taken in cross-section by electron microscopy (right panel); the magnetic layer properties have been optimised to have high flux density, high permeability, low coercivity and low saturation field, has shown in the hysteresis curve represented in the left panel

Photograph of the Hall sensor with detail of the magnetic layer taken in cross-section by electron microscopy (right panel); the magnetic layer properties have been optimised to have high flux density, high permeability, low coercivity and low saturation field, has shown in the hysteresis curve represented in the left panel

Reference: https://doi.org/10.1051/epjconf/20134016002

Main publications

- “Stripe domains reorientation in ferromagnetic films with perpendicular magnetic anisotropy” – L.-C. Garnier, M. Marangolo, S. Fin, F. Casoli, M. G. Pini, M. Eddrie, A. Rettori, D. Bisero, S. Tacchi – J. Phys.: Mater. 3 (2020) 024001 – https://doi.org/10.1088/2515-7639/ab6ea5

- “Exchange-Coupled Composite Media” – F. Casoli, L. Nasi, F. Albertini, P. Lupo – in Ultra-High-Density Magnetic Recording: Storage Materials and Media Designs, pp 279-326, Pan Stanford Publishing, 2016. Editors: G. Varvaro, F. Casoli.

- “Hall current sensor IC with integrated Co-based alloy thin film magnetic concentrator” – V. Palumbo, M. Marchesi, V. Chiesi, D. Paci, P. Iuliano, F. Toia, F. Casoli, P. Ranzieri, F. Albertini, M. Morelli – EPJ Web of Conferences 2013 vol. 40, 16002 – https://doi.org/10.1051/epjconf/20134016002

-

“Strong coercivity reduction in perpendicular FePt/Fe bilayers due to hard/soft coupling” – F. Casoli, F. Albertini, L. Nasi, S. Fabbrici, R. Cabassi, F. Bolzoni, C. Bocchi – Appl. Phys. Lett. 92 (2008) 142506 – https://doi.org/10.1063/1.2905294